DIY Foil Kites

-

Kevin Brooker

- Medium Poster

- Posts: 53

- Joined: Sat Nov 19, 2016 3:53 am

- Style: snow

- Gear: Home sewn

- Brand Affiliation: None

- Has thanked: 0

- Been thanked: 3 times

Re: DIY Foil Kites

Great job on the sewing. What type of knot do you use on the bridles? What is your method for getting each line the correct length?

-

stefmoris

- Medium Poster

- Posts: 83

- Joined: Sat Aug 13, 2011 9:56 am

- Local Beach: Puntone

- Gear: Mikeslab Bullet (3,4,.....)

- Brand Affiliation: lecca-lecca / Mikeslab

- Location: Italy

- Has thanked: 0

- Been thanked: 4 times

- Contact:

Re: DIY Foil Kites

Thanks guys for the nice comments.

Kitexpert I'm doing it exactly as you describe, I just use a ribbon/strap at the trailing edge to keep the material from stressing the taped seam before it's stitched (because I use tape).

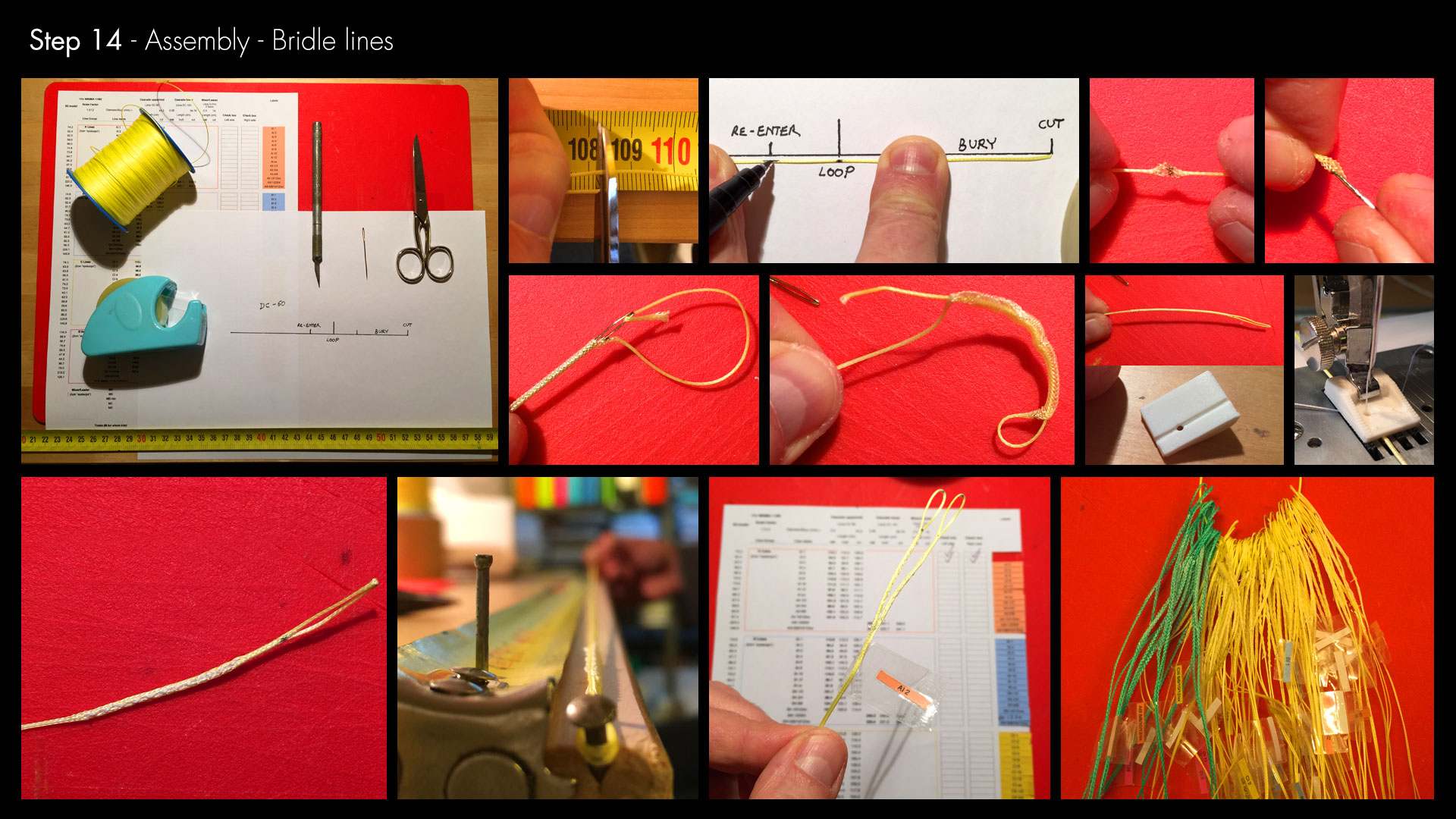

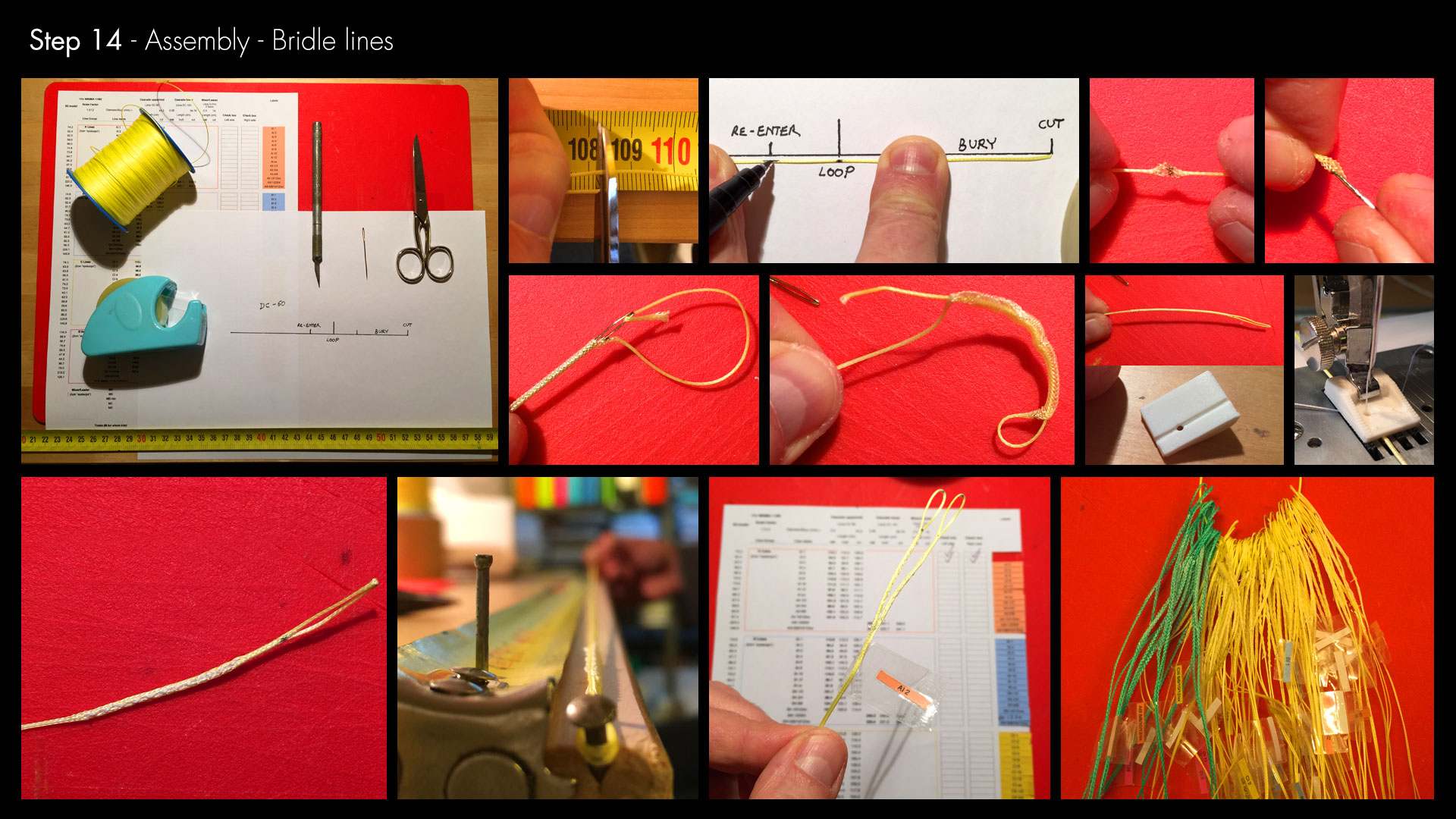

Kevin I'll get around to the lines next week (with pics) but I fingertrap/splice and sew all my lines, no knots. For lengths I just work on pairs at a time and apply similar tension by hand, cutting first my calculated raw length needed (I test both the splicing and connection between lines for each line type used in order to calculate final mounted lengths.), then adjusting the spliced loop to get length perfect.

Kitexpert I'm doing it exactly as you describe, I just use a ribbon/strap at the trailing edge to keep the material from stressing the taped seam before it's stitched (because I use tape).

Kevin I'll get around to the lines next week (with pics) but I fingertrap/splice and sew all my lines, no knots. For lengths I just work on pairs at a time and apply similar tension by hand, cutting first my calculated raw length needed (I test both the splicing and connection between lines for each line type used in order to calculate final mounted lengths.), then adjusting the spliced loop to get length perfect.

-

Kevin Brooker

- Medium Poster

- Posts: 53

- Joined: Sat Nov 19, 2016 3:53 am

- Style: snow

- Gear: Home sewn

- Brand Affiliation: None

- Has thanked: 0

- Been thanked: 3 times

-

foilholio

- Very Frequent Poster

- Posts: 3429

- Joined: Sun Aug 23, 2015 3:20 am

- Local Beach: Ventura Beach

- Favorite Beaches: Tarifa

- Style: Airstyle

- Gear: Foils

- Brand Affiliation: None

- Has thanked: 227 times

- Been thanked: 148 times

Re: DIY Foil Kites

To make even bridles you need to prestretch the line with the same force for all, the more force the better. I usually work on both ends of a prestretched piece of line. I can hook both splices onto a line jig and get the final cut exact , which takes out any error on the first 2 splices. You can hand tune the last 2 splices. If you measure, mark and use pins accurately corrections are rarely needed. There is benefits and negatives to prestretching, the higher the forces the more symmetrical the line is and therefore it is more likely to stay symmetrical even when it shrinks, but the higher the prestretch the more it shrinks :-/

-

foilholio

- Very Frequent Poster

- Posts: 3429

- Joined: Sun Aug 23, 2015 3:20 am

- Local Beach: Ventura Beach

- Favorite Beaches: Tarifa

- Style: Airstyle

- Gear: Foils

- Brand Affiliation: None

- Has thanked: 227 times

- Been thanked: 148 times

Re: DIY Foil Kites

Interesting TE seam, did you allow for it in the original design? I can see some trouble with the 2 untaped parts of the fabric moving a little before sewing. I like the simplicity of it over the flysurfer one, but I still wonder why simply joining the 2 piece of fabric like on PL kites is not acceptable. Less places for sand to get stuck like that.

-

stefmoris

- Medium Poster

- Posts: 83

- Joined: Sat Aug 13, 2011 9:56 am

- Local Beach: Puntone

- Gear: Mikeslab Bullet (3,4,.....)

- Brand Affiliation: lecca-lecca / Mikeslab

- Location: Italy

- Has thanked: 0

- Been thanked: 4 times

- Contact:

Re: DIY Foil Kites

Hi Foilholio, I do account for the seam allowance for my trailing edge when creating my patterns. I've never seen how PL does it so I'd love to see a pic if you have one. I did it this way on my last two kites and it worked great. I do it this way mainly because it is easy to undo with a seamripper in case I ever have to go inside for repair. It doesn't trap sand and has minimal thickness when sewing (as opposed to a rolled seam) -stef

-

stefmoris

- Medium Poster

- Posts: 83

- Joined: Sat Aug 13, 2011 9:56 am

- Local Beach: Puntone

- Gear: Mikeslab Bullet (3,4,.....)

- Brand Affiliation: lecca-lecca / Mikeslab

- Location: Italy

- Has thanked: 0

- Been thanked: 4 times

- Contact:

Re: DIY Foil Kites

Bridles complete, on to the mixer next. The yellow line in the images is Liros DC 60, and the green Liros DC 161. I made my own custom presser foot to work with the DC 60 as it is so thin. -stef

-

kitexpert

- Very Frequent Poster

- Posts: 1417

- Joined: Sun Aug 09, 2015 11:20 pm

- Gear: many kites, also diy

- Brand Affiliation: None

- Has thanked: 55 times

- Been thanked: 136 times

Re: DIY Foil Kites

Thanks again, stef. I think this thread is becoming the best how to make a foil kite presentation I have seen

To make dedicated presser foot for sewing the lines is very nice. I have managed with ordinary one, (I have some with grooves on bottom) but like you say it is tricky (almost impossible) work if line is thin. I've used quite a lot recycled lines from pg's and old kites, then at least one end is spliced/sewed. Other end is ok with knotted loop, especially if joined (by LCL) near canopy there is not much risk of tangles.

I strongly recommend LCL's, they make installing and servicing the bridle much easier. It is also possible to use them as an adjusters for single bridle lines, for example if wingtip area needs precise tuning.

It is best to splice/sew thicker lines of upper levels, knotted loops there are a bit too clumsy and catch other lines too easily.

PL TE is simplest possible, upper and lower skins are taped/glued together and then sewed through. No folds, just one straight stitch. No doubt folded TE is stronger, but is there any benefit of that, hard to say. If brakes are at TE, then folded TE is more needed if not obligatory. I don't think drag wise there is much difference, miniribs and/or narrow enough cell width is more important. Also how TE draining is designed has an effect on how flat TE will be. PL's mesh part is better than cut profile end, which causes small bulging there. But again, how essential this is, many race kites use cut ribs.

To make dedicated presser foot for sewing the lines is very nice. I have managed with ordinary one, (I have some with grooves on bottom) but like you say it is tricky (almost impossible) work if line is thin. I've used quite a lot recycled lines from pg's and old kites, then at least one end is spliced/sewed. Other end is ok with knotted loop, especially if joined (by LCL) near canopy there is not much risk of tangles.

I strongly recommend LCL's, they make installing and servicing the bridle much easier. It is also possible to use them as an adjusters for single bridle lines, for example if wingtip area needs precise tuning.

It is best to splice/sew thicker lines of upper levels, knotted loops there are a bit too clumsy and catch other lines too easily.

PL TE is simplest possible, upper and lower skins are taped/glued together and then sewed through. No folds, just one straight stitch. No doubt folded TE is stronger, but is there any benefit of that, hard to say. If brakes are at TE, then folded TE is more needed if not obligatory. I don't think drag wise there is much difference, miniribs and/or narrow enough cell width is more important. Also how TE draining is designed has an effect on how flat TE will be. PL's mesh part is better than cut profile end, which causes small bulging there. But again, how essential this is, many race kites use cut ribs.

-

foilholio

- Very Frequent Poster

- Posts: 3429

- Joined: Sun Aug 23, 2015 3:20 am

- Local Beach: Ventura Beach

- Favorite Beaches: Tarifa

- Style: Airstyle

- Gear: Foils

- Brand Affiliation: None

- Has thanked: 227 times

- Been thanked: 148 times

Re: DIY Foil Kites

PLs I have seen use a 3 step zigzag and not a straight stitch on the TE. Whats the strength difference between zigzag and 3 step zigzag?

Who is online

Users browsing this forum: Avo and 84 guests