Page 2 of 3

Re: 3D Printed Wings - please post your experiences here

Posted: Thu Sep 13, 2018 7:42 pm

by faklord

For info, I have recently purchased the Ender 3 and have been very impressed with the both the quality of the build of the printer and also of the of print results.

Re: 3D Printed Wings - please post your experiences here

Posted: Sat Oct 06, 2018 8:41 pm

by direnc

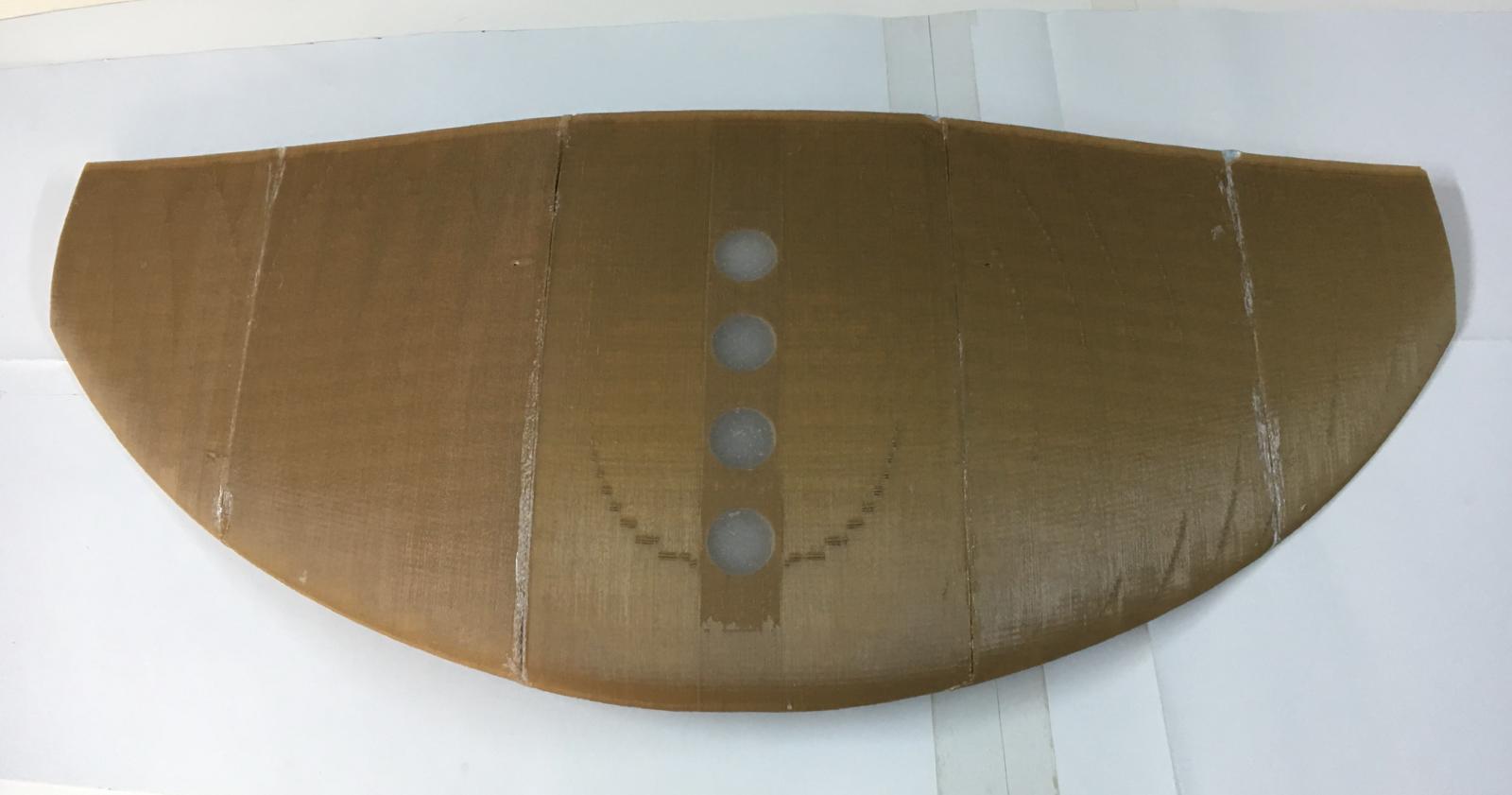

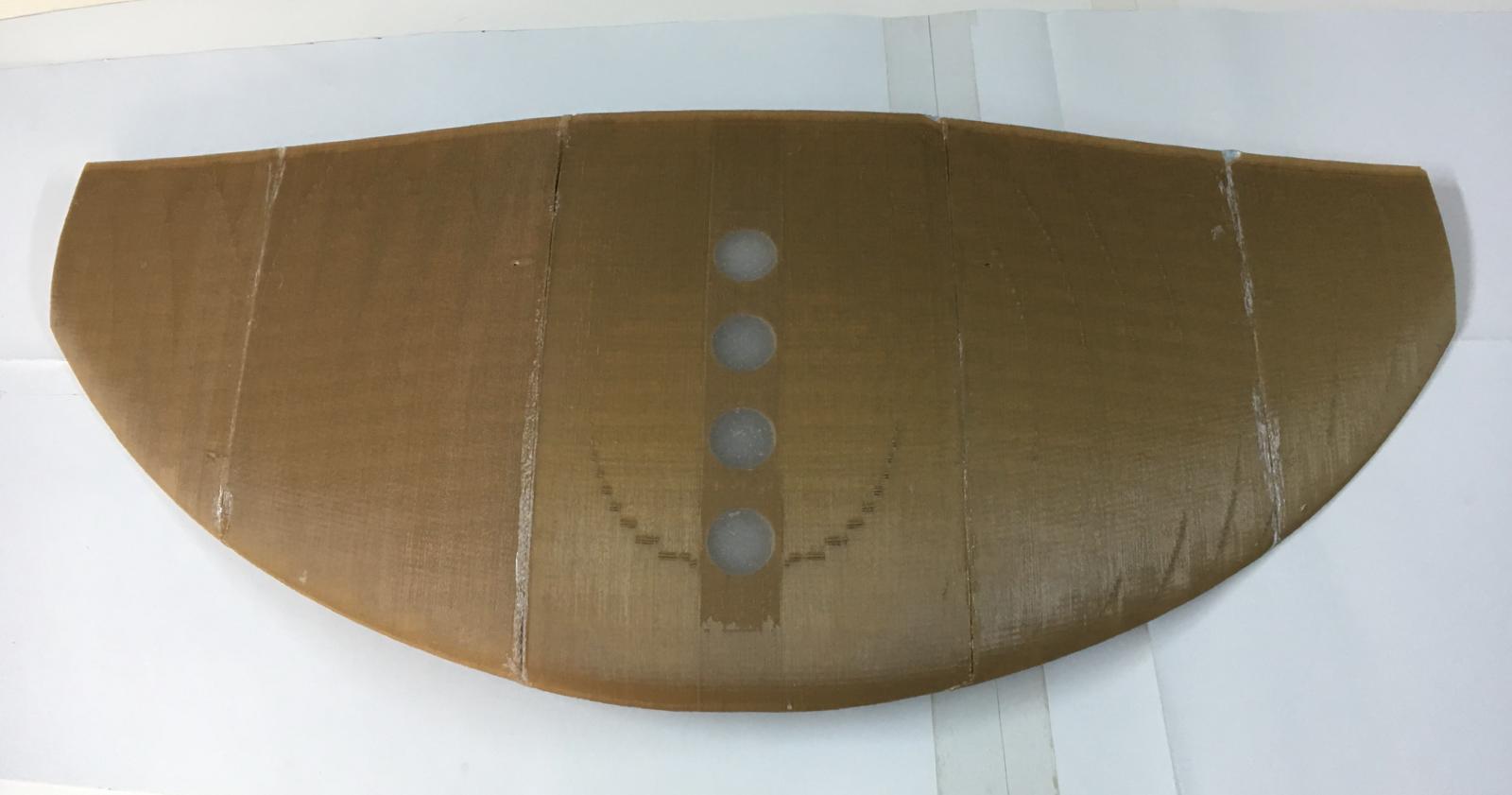

As I mentioned before, I designed a front wing meant to be strong enough to fly without any lamination, straight out of the printer. The wing has two embedded 42cm 8x8mm square stainless steel rods.

Wing specs:

Span: 52cm.

Chord 26cm.

Profile H105.

Surface area 1000cm2.

Weight 1400grams (900grams of PLA + steel rods... Wonder if it could be built lighter)

Mounting hardware: M8

I gave it to my friend to test, and he reports it's a very nice wing, and did not fail during his ride. I will fly it myself next time I go foiling.

Below are some pictures. I can upload the cad files to Thingiverse if there's any interest.

Re: 3D Printed Wings - please post your experiences here

Posted: Sat Oct 06, 2018 10:33 pm

by TomW

Really cool. Why not use carbon tubes/ bars instead of ss?

And one layer of glass would be really easy.

Trouble with inner spar is the wing has to be flat.

Re: 3D Printed Wings - please post your experiences here

Posted: Sat Oct 06, 2018 11:53 pm

by TheJoe

I started building a 3d printed foil. I have the mast pieces printed but suffered a pectoral tear and have been laid up unable to start the carbon layup.

I would recommend some fiberglass or carbon. Since you did a vertical print I bet your wing tips break off. If you wanted to loose weight carbon rods or straight carbon layup with a 10-20% infill. I have a few weeks and I will be able to start working on my build again.

It does look good so good job.

Re: 3D Printed Wings - please post your experiences here

Posted: Sun Oct 07, 2018 1:42 pm

by faklord

direnc - Great stuff!! I have to hand it to you for your pioneering work

I'd be interested to look at the design if you want to drop it onto Thingiverse. Preferably, if possible, including pre-meshed design files ?

It must have taken quite a while to print this!

Did you build washout into the tips on this one?

As with any designs (whether they be a success or fail), any info on:- infill, skin thickness etc would be useful.

As others have suggested, a carbon (or glass) skin could replace the SS rods, making the wing both stronger, lighter and giving more options for shape... But I suspect your aim was to see if a wing could be made to work straight off the printer?

Re: 3D Printed Wings - please post your experiences here

Posted: Sun Oct 07, 2018 9:31 pm

by direnc

I have already built a 3D printed and then laminated wing before. This time I was just curious to see if it would be possible to build one that will be strong enough without lamination.

The wing has -3 degrees of washout toward the tips. BTW I tried it today, and it flies very well.

I uploaded the Fusion 360 file, stl files and print settings to Thingiverse

https://www.thingiverse.com/thing:3142480.

It took about 40 hours to print.

There's a slight problem, though. I weighed the wing again, and it's 1600 grams now. It's taking in water. Maybe i should have printed it at higher temperature, or annealed it in the oven. Maybe it developed some micro cracks for water to enter, I do not know.... So it should be painted/sealed before using...

Re: 3D Printed Wings - please post your experiences here

Posted: Mon Oct 08, 2018 11:49 am

by faklord

Water ingress!

This is a real shame and might be a general problem with printed parts in a water environment.

I suppose any design that is not solid has the potential to soak up water.

Apart from the weight issue there is also the possibility of water leaking back out during storage/transport.

Given that knocks and scrapes are inevitable I’m not sure painting/sealing is going to fix the issue. Possibly coating a heated part and then allowing to cool as a sealant sets might help draw the sealant into any the problem areas?

A structure that has multiple solid walls might limit the ingress to local areas rather than whole piece.

It might be interesting to see how your wing balances around the center line to see if it is just one section that has soaked up the water?

Re: 3D Printed Wings - please post your experiences here

Posted: Thu May 16, 2019 11:12 pm

by kjorn

What software are you using? I've tried SketchUP and it works OK for building a wing, but I can't figure out how you punched square holes through the wing? Could you give me some tips please

Second question, did you do anything to the surface of the wing before laminating it? I am thinking of drilling some small holes through it, them pushing carbon fibre through the holes and epoxy. Then laminate, the top and bottom skins will be attached via the little holes filled with carbon and epoxy.

Re: 3D Printed Wings - please post your experiences here

Posted: Fri May 17, 2019 6:55 am

by longwhitecloud

You could build in tapered flanges on each part end - that act as "fins" that have countersunk nuts and bolt holes to secure it together. Add a gasket slot and gasket.. ?

i guess you can print closed cells too.

Re: 3D Printed Wings - please post your experiences here

Posted: Fri May 17, 2019 7:28 am

by direnc

kjorn wrote: ↑Thu May 16, 2019 11:12 pm

What software are you using? I've tried SketchUP and it works OK for building a wing, but I can't figure out how you punched square holes through the wing? Could you give me some tips please

I am using Fusion 360. Don't know about SketchUP, but it should only be a matter of drawing the hole pattern and then extruding it.

kjorn wrote: ↑Thu May 16, 2019 11:12 pm

Second question, did you do anything to the surface of the wing before laminating it? I am thinking of drilling some small holes through it, them pushing carbon fibre through the holes and epoxy. Then laminate, the top and bottom skins will be attached via the little holes filled with carbon and epoxy.

The wing above has only two steel rods inside, and no lamination. For the wing that I laminated, I did not do anything to the surface. I have now have two other wings that I am building. For these I made the screw holes oversize, and filled them with epoxy. One of the wings I printed using the Fuzzy skin feature of Cura for a better bond. PLA and epoxy don't really bond well. I printed and laminated some test pieces, and a fuzzy skin bonds much better.

There are many ways to build a wing. A guy on thingiverse built one of my wings. He filled the voids in the wing with foaming epoxy:

https://www.thingiverse.com/make:584348

The wing with oversize, epoxy filled holes: